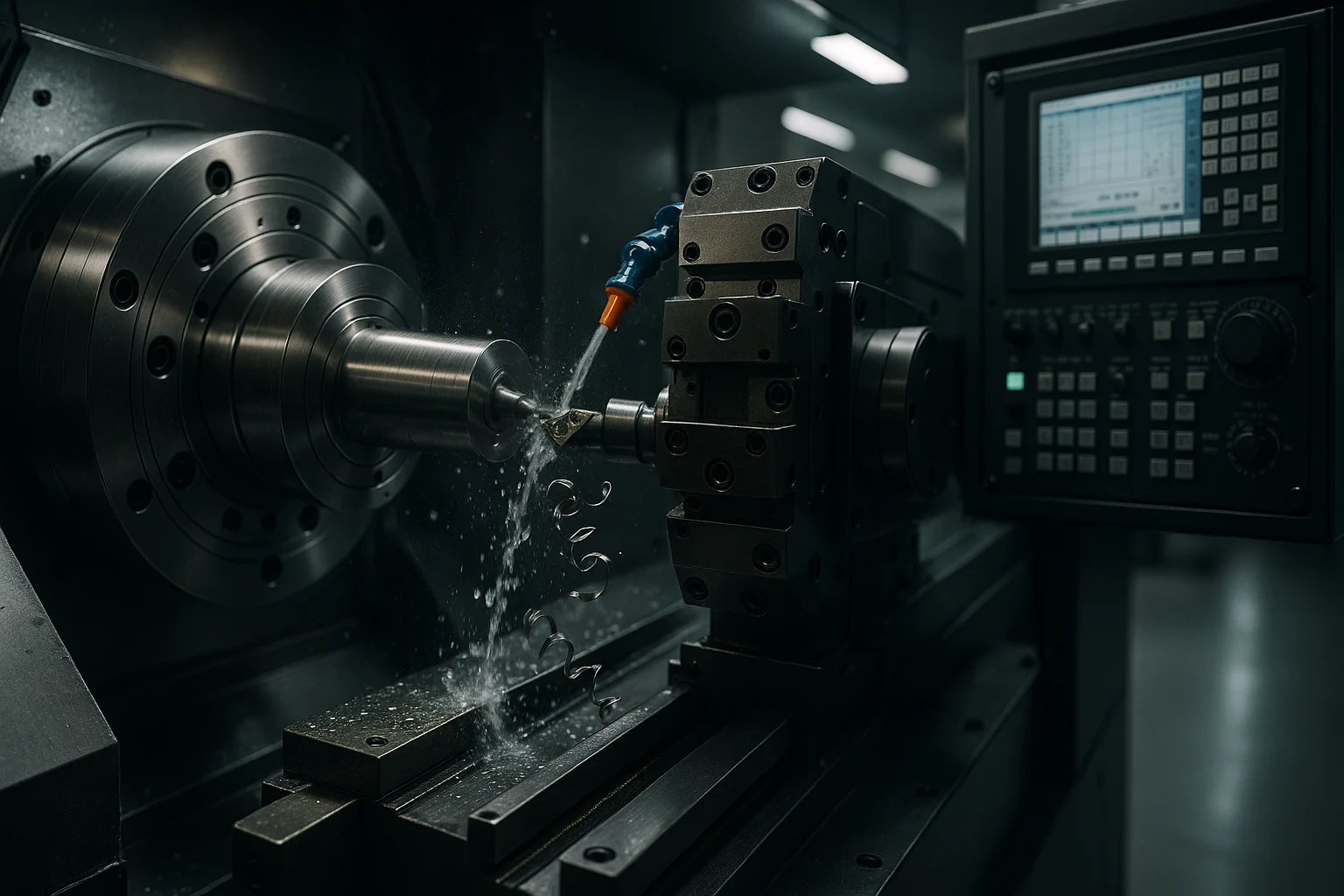

CNC Machining & CNC Turning Services

SARITVAT – Reliable CNC Machining & CNC Turning Solutions for Everyday Precision Needs

CNC machining has become a must-have in modern manufacturing because it delivers clean, accurate, and repeatable results every single time. At SARITVAT, we work closely with our Vendors and engineering teams to create custom CNC-machined parts for a wide range of industries — including automotive, aerospace, and medical — while keeping the process clear, friendly, and easy to follow.

With advanced CNC equipment and a team that truly understands complex geometries, tight tolerances, and real-world production challenges, we keep your project stress-free. Our transparent approach ensures you always know which Supplier materials, specifications, and inspections are being used — and why. CNC turning also plays a major role here: it’s the process of rotating a workpiece while shaping it into exactly the cylindrical form you need. With our precision-driven workflow, we help you make practical Support decisions that reduce risk, improve durability, and keep timelines predictable.

From CNC milling to CNC turning rapid prototyping, our capabilities support everything from small prototype batches to full-scale mass production. We maintain quality across all our qualified Suppliers and audited partners, ensuring every part consistently meets your requirements. Whether you're a procurement team, a quality lead, or a Manufacturer looking for predictable, reliable output — we've got your back.

Benefits of CNC Machining & CNC Turning Technology

Get highly accurate, repeatable components with clear documentation that helps teams in local facilities make quick and confident decisions.

Automated CNC setups minimize manual errors, save time, and maintain strong traceability across approved nearby production units.

Perfect for both low-volume and bulk orders; we schedule production with a balance of urgency, cost, and smooth communication.

Superior CNC turning surface finish for both performance and visual appeal.

Rapid CNC turning prototypes help teams make fast, data-based design and tolerance decisions.

Optimized workflows reduce lead time without affecting safety or ethical sourcing.

Smooth movement from design to production with constant visibility and dedicated Support at every stage.

Enhanced CNC precision ensures consistent results across large batch runs and multi-site Vendor production.

Industrial Applications and Use Cases

Automotive: Shafts, bushings, pulleys, bolts — all delivered with PPAP-ready documentation.

Aerospace: Structural components and engine nozzles produced under strong process control and material traceability.

Medical: Orthopedic implants and surgical tools made with strict inspection and validation steps.

Electronics: Heat sinks, connectors, and parts designed with thermal performance in mind.

General manufacturing: Custom fixtures, jigs, and parts aligned with lean manufacturing needs.

Prototyping: CNC turning rapid prototypes to validate ideas quickly and reduce overall development costs.

Industrial automation: Precision parts for machinery, coordinated with approved Suppliers for smooth replacements.

Materials Used in CNC Machining & CNC Turning

Aluminum Alloys: Lightweight, corrosion-resistant, and perfect for fast iterations.

Stainless Steel: Strong, durable, and ideal for high-demand or hygiene-critical applications.

Brass & Copper: Excellent for electrical and thermal applications like terminals and connectors.

Plastics: ABS, Nylon, PEEK, and more — ideal for lightweight and application-specific performance.

Titanium: High strength-to-weight ratio for aerospace and defense-level precision needs.

How Costing Works in CNC Machining Projects

Several factors influence CNC machining costs — including material type, design complexity, and batch size. Smaller quantities require flexible setups, while larger runs benefit from economies of scale. At SARITVAT, we fine-tune each CNC turning process to keep costs fair and outcomes consistent. We’re always transparent about make-versus-buy decisions so teams can coordinate efficiently with their Supplier network. Our CNC turning process optimization helps reduce waste and lead time, making production practical for both low and high volumes with predictable results.

Alternative Technical Solutions

CNC milling for flat and non-cylindrical components that require smooth surfaces.

Wire EDM for clean, burr-free edges and precise cuts in conductive materials.

5-Axis CNC machining for complex multi-angle parts needing minimal setups.

Additive manufacturing for quick prototypes and early-stage functional testing.

Waterjet cutting for heat-sensitive materials that must retain structural integrity.

FAQs

Q: What is CNC machining?

A:

CNC machining is a fully automated subtractive

method where computer-controlled tools cut

material to create precise custom parts. We

maintain clear, friendly communication with

engineering, purchasing, and Vendors

throughout the process.

Q: What is CNC turning?

A:

CNC turning shapes a rotating workpiece using a

fixed cutting tool, allowing accurate production

of cylindrical components. We coordinate

material and finishing choices with your

preferred Supplier to match your

standards.

Q: How does CNC turning differ from CNC

milling?

A: Turning rotates the

material, making it ideal for round or

symmetrical parts. Milling keeps the material

still while tools cut across it — perfect for

flat, angled, or complex shapes. This helps

Manufacturers pick the right process for

cost and performance.

Q: What industries benefit from CNC

machining?

A: Automotive,

aerospace, electronics, medical, and many more —

basically anyone who needs high-precision parts,

compliance support, and reliable technical

Support.

Q: How does CNC turning support

low-volume production?

A: With

automated setups and rapid prototyping, small

batches become fast, cost-effective, and

consistent — great for pilot builds and

local testing.

Q: What is CNC turning process

optimization?

A: It’s the

fine-tuning of settings, tool paths, and

workflows to boost productivity, maintain

quality, and minimize waste. We share all

relevant data with your quality teams and

trusted Suppliers.

Q: Can SARITVAT create custom parts for

unique applications?

A:

Absolutely! We specialize in customized parts

across multiple industries and coordinate with

nearby labs and logistics teams for

faster cycles.

Q: What materials work best for CNC

turning?

A: Metals like

aluminum, brass, steel, and plastics such as

ABS, Nylon, and PEEK are commonly used — always

aligned with your preferred Supplier

requirements.

Q: How does SARITVAT ensure good CNC

turning surface finish?

A: With

advanced machines and proper finishing steps, we

achieve smooth textures and accurate dimensions,

sharing measurements openly to help your team

make informed quality decisions.

Q: Why choose SARITVAT for CNC

machining?

A: Because we focus

on accuracy, communication, process clarity, and

dependable results — all supported by ethical

practices and well-coordinated Vendor and

supplier relationships.

By Sea: Asia: 15–20 days, Europe: 25–35 days, North America: 30–40 days, South America: 35–45 days, Middle East: 14–18 days, Africa: 20–28 days, Oceania: 22–30 days

By Air: Asia: 1–3 days, Europe: 3–5 days, North America: 4–6 days, South America: 5–7 days, Middle East: 1–2 days, Africa: 3–5 days, Oceania: 4–6 days