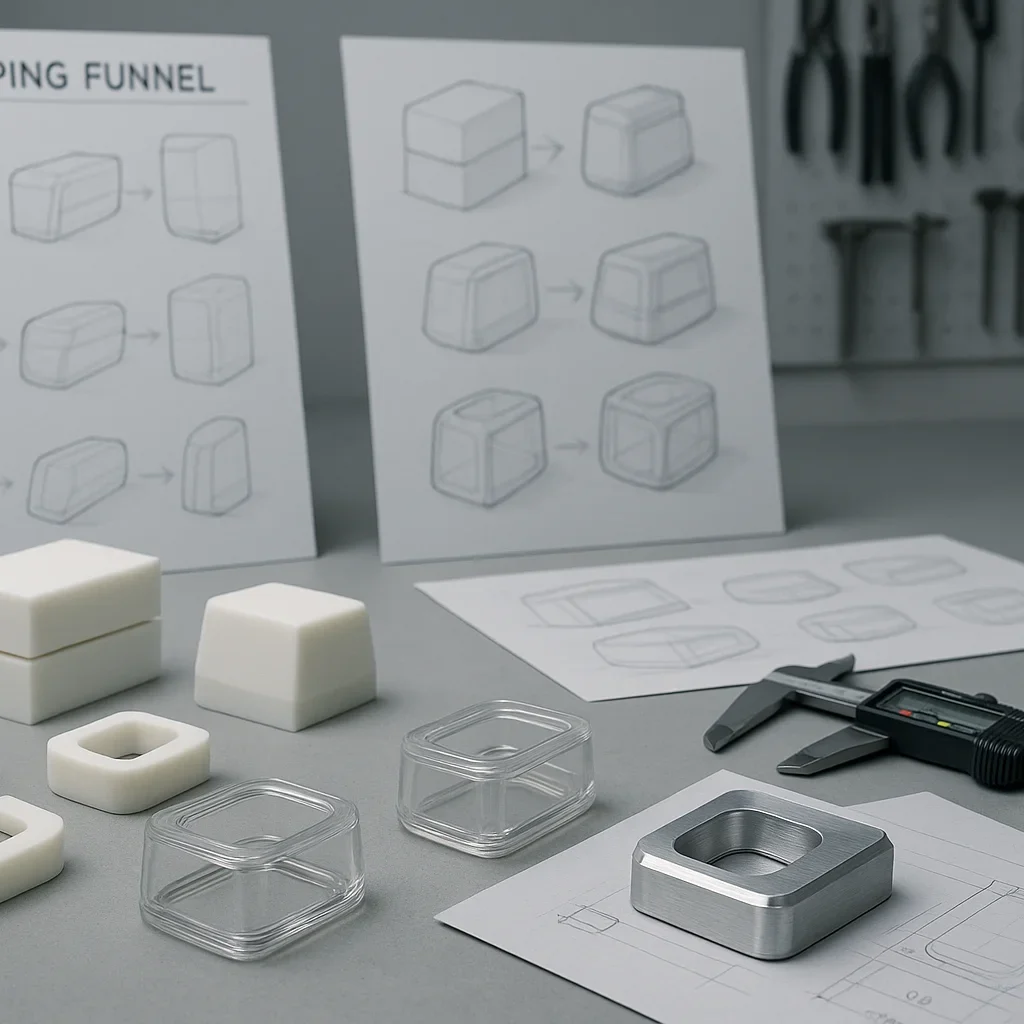

Rapid Prototyping

SARITVAT – Your Partner in Rapid Prototyping and On-Demand Manufacturing

Rapid prototyping is a game-changer, helping companies – from local startups to innovative regional players – turn ideas into real, tangible models quickly and accurately. At SARITVAT, we work hand-in-hand with trusted Vendors and reliable Suppliers to provide a full range of rapid prototyping services for industries like consumer electronics, medical devices, and automotive innovation. Our Manufacturers and Support teams make sure every prototype is delivered on time and ethically produced.

We use a mix of technologies like SLA printing, SLS printing, CNC machining, and CNC routing to deliver fast, flexible, and functional prototypes. By collaborating closely with nearby Suppliers and regional Vendors, we integrate expertise in CNC workflows and machining processes, producing high-quality parts with shorter lead times and lower costs – all backed by our human-focused Support teams and responsible Manufacturers.

From laser cutting for precise sheet fabrication to injection molding for pilot production, SARITVAT is your trusted local partner. We also work with liquid silicone for soft and transparent components, and offer various plastic molding processes for scalable prototyping. Our contract manufacturing team supports the full lifecycle – from early-stage prototype development with local Suppliers to scaling production with ethical Manufacturers and dedicated Vendors.

Benefits of Technology

Quick and cost-effective production of complex designs, thanks to Vendors and Manufacturers who provide local insight and Support to simplify decision-making.

CNC routing and machining ensure precise details, supported by ethical Suppliers and reliable Vendors, with our technical Support guiding every step.

Test multiple design iterations easily with SLA and SLS printing, coordinated by nearby Suppliers and trusted Manufacturers for consistent results.

Create functional prototype units with industrial-grade materials sourced from certified Vendors and supported by local Suppliers and knowledgeable Manufacturers.

Smoothly transition from prototyping to contract manufacturing with help from nearby Vendors, local Supplier networks, and dependable Manufacturers for sustainable scaling.

Produce both hard machined parts and soft liquid silicone models efficiently, supported by ethical Vendors, proactive Suppliers, and collaborative local Manufacturers.

Speed up production with laser cutting and direct-to-fabrication methods, coordinated by nearby Suppliers, responsible Vendors, and local Support engineers.

Perfect for pre-production validation with real-world materials and tolerances, provided by trusted Vendors, ethical Manufacturers, and hands-on local Support.

Industrial Application and Use Cases

Automotive: Gear housings, dashboard panels, and functional lighting prototypes, developed with Vendors, local Suppliers, and automotive Manufacturers offering reliable Support.

Medical Devices: Custom casings using liquid silicone and biocompatible SLA printing, made by Suppliers and Vendors with precision, safety, and ethical Manufacturer oversight.

Aerospace: Lightweight plastic and complex CNC-routed parts provided by nearby Vendors, with full Supplier and Manufacturer Support.

Consumer Electronics: Enclosures, wearables, and small machined parts created by Vendors, handled by regional Suppliers, and validated by local Manufacturers.

Product Design: Concept validation with rapid prototyping, CNC routing, and laser cutting, supported by nearby Manufacturers, local Suppliers, and expert Vendors.

Industrial Tools: Ergonomic handles and fixtures produced with SLS printing and CNC machining, supported by Vendors, Suppliers, and local tooling Manufacturers.

Robotics: Structural frames and brackets fabricated via CNC routing, coordinated with local Manufacturers, ethical Vendors, and dedicated Suppliers.

Startups: Turn your MVP ideas into reality with contract manufacturing Support, ethical guidance, and collaboration from local Vendors, regional Suppliers, and nearby Manufacturers.

Material Used in Technology

ABS and PLA: Common thermoplastics for prototyping, sourced sustainably by local Suppliers and Vendors, supported by nearby Manufacturers.

Resins: Perfect for SLA printing and high-detail prototypes, provided by trusted Vendors and implemented ethically by local Manufacturers with Support.

Nylon and PA12: Durable materials for SLS printing, procured by reliable Suppliers and Vendors to ensure consistent quality for Manufacturers.

Silicone Rubber: Used for flexible parts in liquid silicone molding, sourced through Vendors and handled precisely by Suppliers and Manufacturers.

Acrylic and Polycarbonate: Laser-cut for transparency and strength, provided by ethical Vendors, informed Suppliers, and engineered with local Manufacturer Support.

Aluminum and Steel: Precision machined via CNC, using metal blanks from regional Suppliers and local Vendors, supported by advanced Manufacturers.

Epoxy Composites: Functional prototypes requiring thermal resistance and strength, sourced from supportive Suppliers, processed by Vendors, and guided by Manufacturers with local Support networks.

How Costing Works

Our rapid prototyping pricing is transparent and value-focused. Factors include complexity, material type, Vendor coordination, Supplier sourcing, and Manufacturer precision – all with clear Support communication.

SLA or SLS prototypes are cost-effective for design evaluation, with nearby Suppliers and local Vendors reducing risk and providing reliable Support throughout.

CNC routing and machining costs are slightly higher due to tooling and material, but minimized with guidance from responsible Vendors, nearby Suppliers, and Manufacturers.

Low-run plastic molding or injection molding benefits from economies of scale. Vendors, Suppliers, and Manufacturers collaborate to provide optimized batch pricing with Support at every step.

From laser-cut panels to complete machined parts, transparent pricing ensures value, backed by ethical Vendors, regional Suppliers, and local Manufacturer Support.

Alternative Technical Suggestion

FDM 3D Printing: Entry-level prototyping for form and fit, supported by nearby Suppliers and small-scale Vendors, with scalable options from regional Manufacturers.

Urethane Casting: Ideal for soft parts before silicone molds, supported by Vendors, ethical Suppliers, and nearby Manufacturers for early-stage tooling.

Sheet Metal Fabrication: Alternative to plastic molding for rigid enclosures, coordinated by Vendors and Suppliers with decision-making Support from Manufacturers.

Hybrid Prototyping: Combines CNC routing and SLS printing for structural and aesthetic functionality, executed by ethical Vendors, trusted Suppliers, and local Manufacturers.

RTV Molding: Low-run molds before injection molding, guided by nearby Suppliers, Vendors, and supported by Manufacturers for fast turnaround.

Selective Laser Melting: Metal parts alternative to CNC machining, led by regional Vendors and Suppliers, with support from advanced Manufacturers.

Stereolithography: High-precision prototypes, made possible by nearby Vendors, Suppliers, and expert local Manufacturers.

FAQs

Q: What is rapid

prototyping?

A: Rapid prototyping is a set of techniques to

quickly create a scale model of a part using 3D

data. This includes SLA printing, CNC machining,

and CNC routing, coordinated by local Vendors,

Suppliers, and Manufacturers.

Q: Why use rapid prototyping over

traditional methods?

A: It’s faster, flexible, cost-effective, and

allows testing multiple iterations quickly.

Nearby Vendors, ethical Suppliers, and

supportive Manufacturers make it collaborative

and efficient.

Q: How does CNC routing

help?

A: CNC routing produces precise 2.5D and 3D

components. Local Vendors and Suppliers ensure

timely delivery, while nearby Manufacturers

maintain quality and consistency.

Q: Difference between SLA and SLS

printing?

A: SLA gives high-detail resin parts for form

validation. SLS provides durable powder-based

prototypes. Vendors and Suppliers coordinate

with Manufacturers to choose the best option.

Q: Can I get end-use parts through rapid

prototyping?

A: Yes. Nearby Vendors, reliable Suppliers, and

advanced Manufacturers can produce small-batch

or MVP-ready parts, with full lifecycle Support.

Q: Typical lead times for machined

parts?

A: With streamlined Vendor and Supplier

workflows near local Manufacturers, lead times

can be 2–5 business days, supported by agile

operations and customer-focused Support.

Q: Is liquid silicone molding suitable

for medical prototypes?

A: Absolutely. Biocompatible materials sourced

by Vendors, and ethical Manufacturers deliver

compliant results with ongoing Support.

Q: How does contract manufacturing help

scale from prototype to

production?

A: Nearby Vendors and Suppliers help transition

parts to Manufacturers for mass production, with

SARITVAT Support ensuring quality and

coordination.

Q: Why use laser cutting?

A: Laser cutting shapes flat materials quickly.

Vendors and Suppliers provide input, while

Manufacturers and Support teams ensure

precision.

Q: How to choose between plastic molding

and CNC machining?

A: For higher volumes or hollow parts, plastic

molding is best. For tighter tolerances or

metals, CNC machining is ideal. SARITVAT guides

you through this decision ethically.

A: By Sea: Asia: 15–20 days, Europe: 25–35 days, North America: 30–40 days, South America: 35–45 days, Middle East: 14–18 days, Africa: 20–28 days, Oceania: 22–30 days

By Air: Asia: 1–3 days, Europe: 3–5 days, North America: 4–6 days, South America: 5–7 days, Middle East: 1–2 days, Africa: 3–5 days, Oceania: 4–6 days