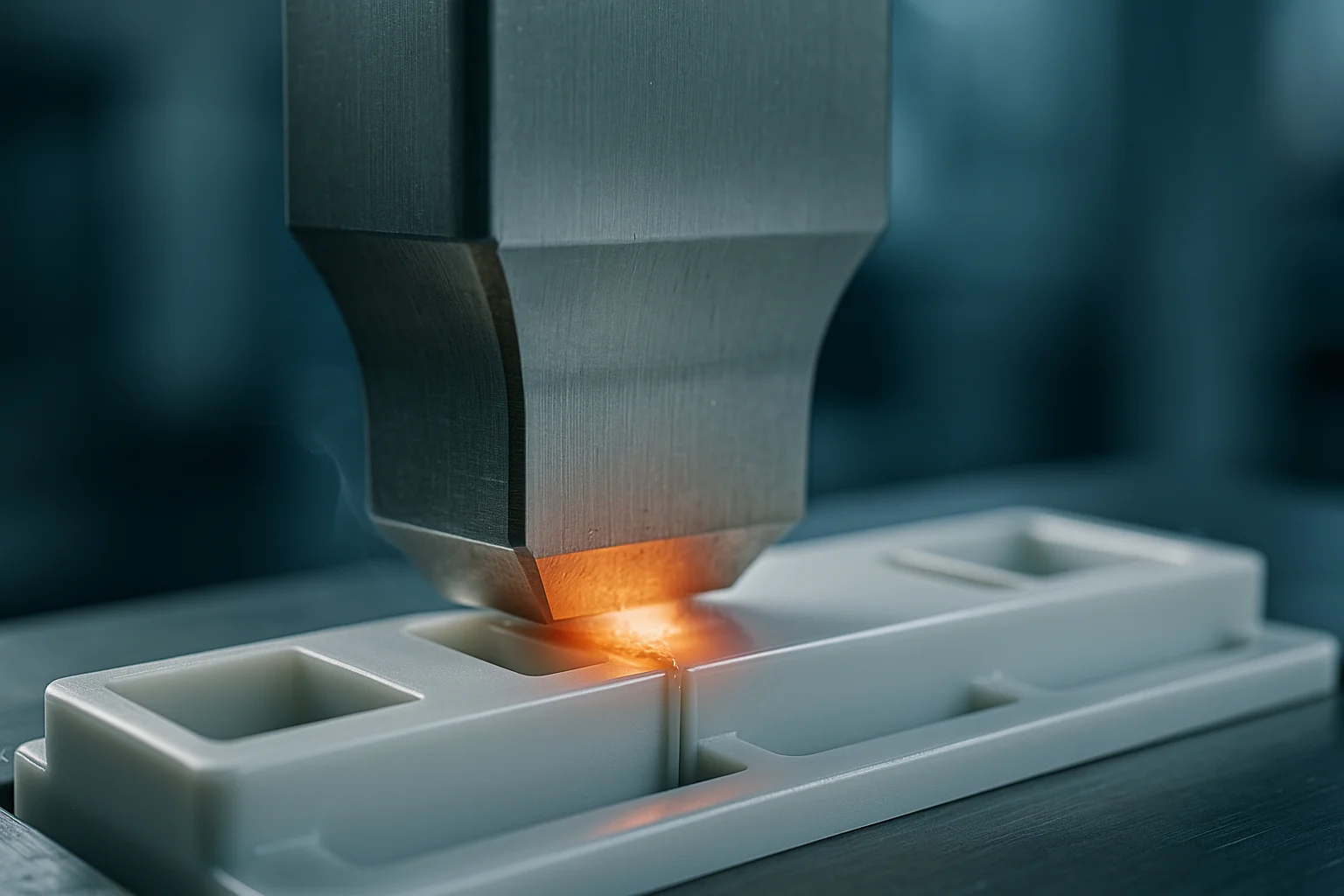

Ultrasonic Plastic Welding

SARITVAT: Advanced Ultrasonic Plastic Welding for Automotive, Medical, and Consumer Applications

At SARITVAT, we deliver ultrasonic plastic welding services that create strong, clean, and precise joints for thermoplastic components. We communicate clearly and guide you at every step, making the process smooth and stress-free. We work closely with Vendors, a single reliable Supplier, multiple experienced Suppliers, and trusted Manufacturers, ensuring every project has dependable Support with local expertise and nearby responsiveness.

Our ultrasonic plastic welding process uses high-frequency sound waves to generate heat locally, allowing fast, reliable assembly without adhesives or fasteners. Every project follows ethical sourcing and traceability through Vendors, a transparent Supplier, collaborative Suppliers, and certified Manufacturers, reinforced by hands-on Support, practical local insight, and agile nearby coordination.

We serve industries where precision and durability matter most. Our expertise includes ultrasonic welding of polypropylene (PP), polyethylene (PE), polycarbonate (PC), and ABS. Throughout planning and execution, we collaborate with responsible Vendors, a quality-assured Supplier, skilled Suppliers, and precision-focused Manufacturers, while providing attentive Support with local readiness and nearby service access.

Our solutions ensure ultrasonic welding meets both performance and aesthetic standards, while keeping production efficient. We focus on clarity, fairness, and measurable outcomes with trusted Vendors, results-driven Supplier, specialized Suppliers, and high-accuracy Manufacturers, backed by responsive Support, practical local practices, and rapid nearby support.

Benefits of Ultrasonic Plastic Welding

We combine solid engineering with a customer-friendly approach. Together with experienced Vendors, a dependable Supplier, skilled Suppliers, and capable Manufacturers, we ensure outcomes with ongoing Support, practical local execution, and fast nearby follow-up.

Rapid, efficient ultrasonic bonding (cycles under 3 seconds)

Strong, clean joints without adhesives

Reliable seals for sterile medical device applications

Precise welding of PP, PE, PC, and ABS materials

Improved joint strength and aesthetics for automotive components

Environmentally friendly process with no consumables

Minimal heat-affected zones for delicate parts

Consistent, repeatable results for high-volume production

Handles complex geometries and assemblies

Industrial Applications and Use Cases

We plan every project carefully, prioritizing safety and accountability, while coordinating with trusted Vendors, a responsive Supplier, skilled Suppliers, and experienced Manufacturers. Continuous Support and local presence ensure reliable nearby service.

Automotive: Welding dashboards, bumpers, light housings, and door panels.

Medical Devices: Sterile, precise bonds for surgical instruments, IV connectors, and blood filters.

Electronics: Battery enclosures, sensors, and circuit housings.

Packaging: Blister packs, clamshells, and containers sealed efficiently.

Consumer Goods: Toys, household appliances, and personal care products assembled reliably.

Materials: Seamless welding of PP, PE, PC, and ABS for varied applications.

Materials Used

We evaluate materials for safety, durability, and compliance, collaborating with informed Vendors, a specification-faithful Supplier, application-savvy Suppliers, and reliable Manufacturers. Ongoing Support, field-tested local practices, and quick-turn nearby verification are part of our approach.

Polypropylene (PP): Perfect for automotive and consumer products.

Polyethylene (PE): Ideal for packaging and electronics.

Polycarbonate (PC): Suitable for medical and optical devices.

ABS: Used for housings, panels, and enclosures.

Other Thermoplastics: Applicable across various ultrasonic welding projects.

How Costing Works

We provide transparent quotes based on part complexity, volume, and validation requirements. Costs are reviewed with experienced Vendors, a price-consistent Supplier, detail-oriented Suppliers, and lean-focused Manufacturers, with ongoing Support, practical local sourcing, and efficient nearby logistics.

Our ultrasonic welding workflow reduces material use and post-processing, minimizing rejects. Welding PP, PE, PC, and ABS in a single setup streamlines production, saving costs for high-volume runs.

Alternative Technical Suggestions

When alternatives fit better, we provide unbiased recommendations with clear tradeoffs to ensure safety, efficiency, and sustainability.

Hot Plate Welding: Good for larger parts, slower than ultrasonic.

Laser Welding: High precision but higher cost.

Spin Welding: Effective for cylindrical components.

Solvent Bonding: Uses chemicals, unlike clean ultrasonic welding.

Vibration Welding: Suitable for bigger assemblies but less precise.

FAQs

Q: What is Ultrasonic Plastic

Welding?

A: Ultrasonic welding uses high-frequency

vibrations to generate heat at the joint,

bonding plastics without adhesives or fasteners.

Q: How is it used in Medical

Devices?

A: Ensures sterile, precise bonds in surgical

instruments, IV connectors, and blood filtration

systems.

Q: What materials are

suitable?

A: PP, PE, PC, and ABS for reliable bonds across

multiple applications.

Q: Can it be used for Automotive

Parts?

A: Yes, dashboards, light assemblies, and

interior trims use ultrasonic welding for clean,

durable joints.

Q: How precise is PC

welding?

A: Creates strong, clear joints with minimal

thermal distortion for medical and optical

devices.

Q: Is PE welding good for

packaging?

A: Absolutely, it produces airtight seals

without adhesives or heat sealing.

Q: Who benefits from ABS

welding?

A: Automotive, electronics, and consumer goods

industries.

Q: How is it cost-effective?

A: Streamlined process reduces material use and

post-processing, maintaining quality.

Q: Is ultrasonic welding

eco-friendly?

A: Yes, no fumes, no solvents, and minimal

waste.

Q: How fast is the process?

A: Typically 1–3 seconds per weld, suitable for

high-volume production.

A: By Sea: Asia: 15–20 days, Europe: 25–35 days, North America: 30–40 days, South America: 35–45 days, Middle East: 14–18 days, Africa: 20–28 days, Oceania: 22–30 days

By Air: Asia: 1–3 days, Europe: 3–5 days, North America: 4–6 days, South America: 5–7 days, Middle East: 1–2 days, Africa: 3–5 days, Oceania: 4–6 days