Vacuum Casting Services

Vacuum casting is a great option when you need small batches of high-quality parts without the heavy costs and long timelines of traditional injection molding. It uses polyurethane resins that closely mimic the performance of engineering plastics, making it perfect for quick, reliable prototype or low-volume production.

The process begins by creating a silicone mold around a master model. This model can be made using various 3D printing technologies such as stereolithography. Once the silicone is poured, a vacuum removes trapped air and the mold is cured in an oven. When the mold is ready, it’s carefully cut open to release the master model, leaving behind a clean, accurate cavity.

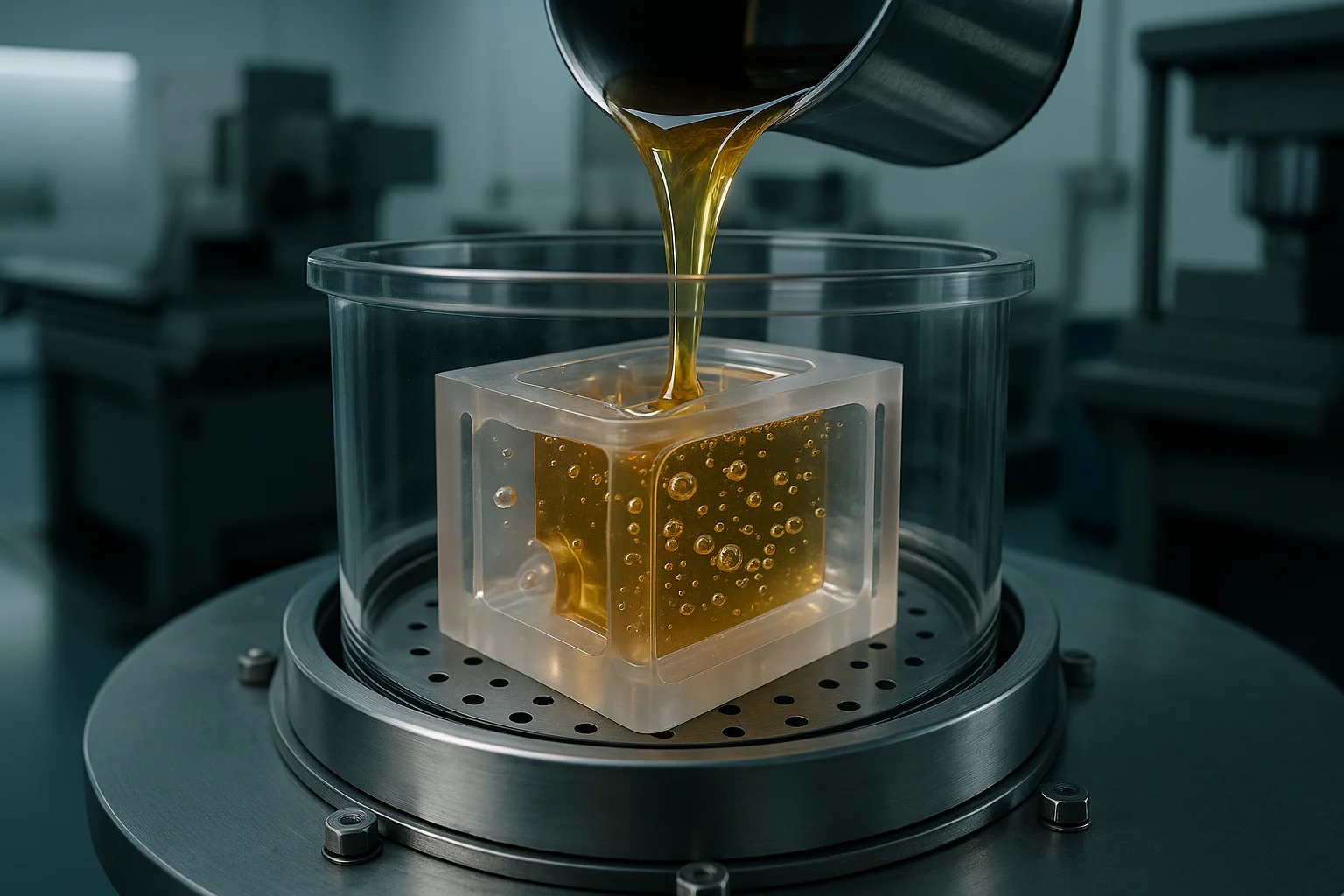

To cast a part, the mold pieces are reassembled, secured, and preheated before being placed inside the vacuum casting chamber. The resin—two or three parts depending on the material—is weighed, mixed, and pigmented if needed. From here, the vacuum casting system handles everything: mixing, degassing, and filling the mold. After casting, the part is cured at 70°C, the mold is opened, and the part is removed.

All that’s left is to trim and finish the part based on your requirements.

Benefits of Vacuum Casting

- Quick turnaround — multiple parts from a single master model within 24 hours, reducing development time and cost.

- Perfect for small batches of high-quality prototypes or low-volume end-use products.

- Wide range of resins available — including food-grade, transparent, flame-retardant, and colored options.

- Long mold life — each mold can typically produce up to 50 parts before replacement is needed, making it ideal for short-run manufacturing.

- Highly flexible — resin types can be changed quickly with minimal system downtime.

- Master models can be created using many sources, including 3D printers, which are now more accessible than ever.

- Handles complex geometries easily with multisegment molds.

Typical Applications of Vacuum Casting

- High-quality prototypes for product design and testing.

- Small-batch production for custom or niche products.

- Functional nylon components in various grades — excellent for living hinges and high-strength parts.

- Automotive testing, including “hot test” applications and specialty manufacturing.

- Production of high-quality wax masters for investment casting.

- Flexible parts using Vario Vac technology.

System Configuration

- Vacuum casting module — ideal for plastic prototypes and low-volume production using polyurethane casting resins.

- Nylon casting module — designed for making nylon and filled-nylon prototypes and final-use parts.

- Heated cup for wax masters — used to create wax models for investment casting or low-melting-point alloy components.

- Vario Vac — suitable for producing silicone rubber prototypes and parts made from highly filled viscous materials.

Vacuum Casting Ancillaries

- Nylon module — allows the creation of strong, functional components in PA6 nylon.

- Curing ovens — available in analogue and digital models for curing molds and materials.

- Extension chamber — useful for oversized projects that exceed standard system capacity, compatible with the 5/04 vacuum casting system.

- Twin robot — increases casting output and efficiency, available for the 5/04 system.

- Fume and dust benches — help maintain a clean, safe environment for operators while ensuring consistent part quality.

- Training programs — customized sessions designed to match your operational needs.